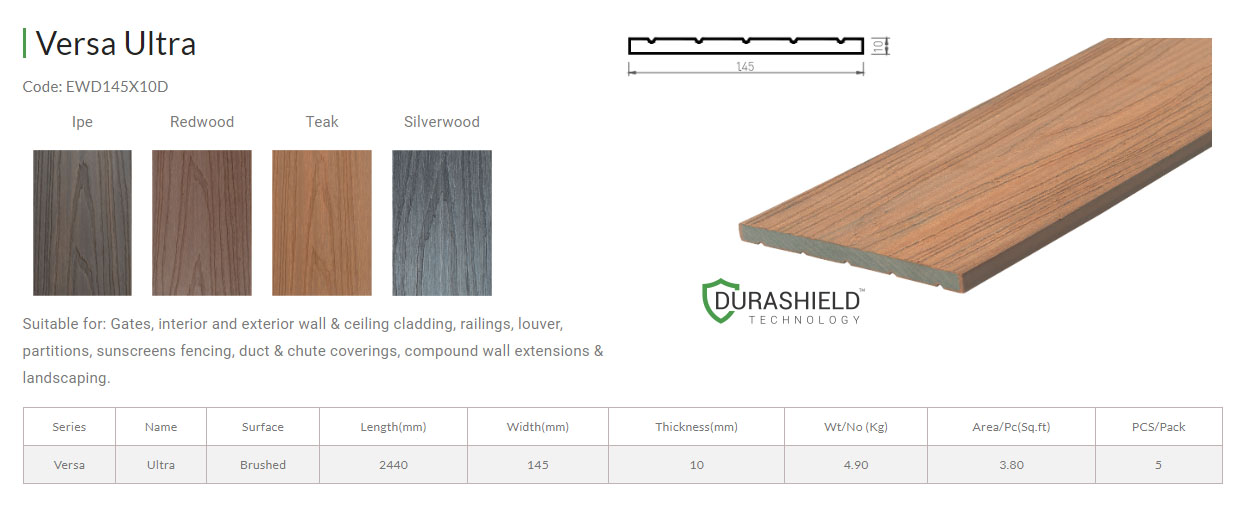

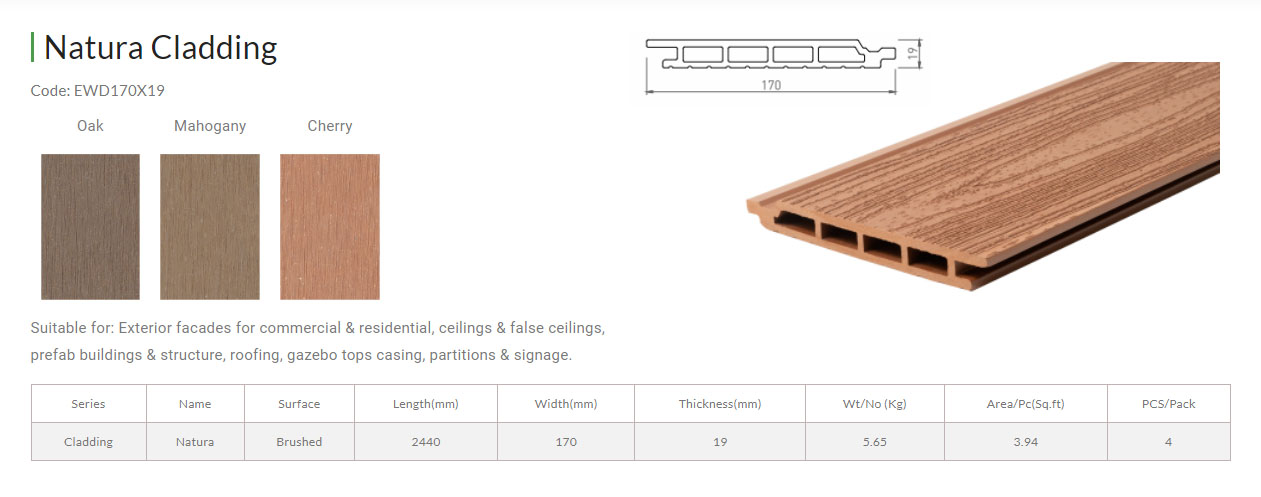

Enhancing Wood Composites With Unmatched Durability And Performance In Extreme Weather Conditions

Durashield is Everwood’s game changing co-extrusion technology that delivers an exceptional combination of aesthetics and product performance. In comparison to conventional standard WPC, Durashield co-extrusion products are a lot more attractive, exceptionally durable in exterior weather conditions and highly resistant to fading and scratching.

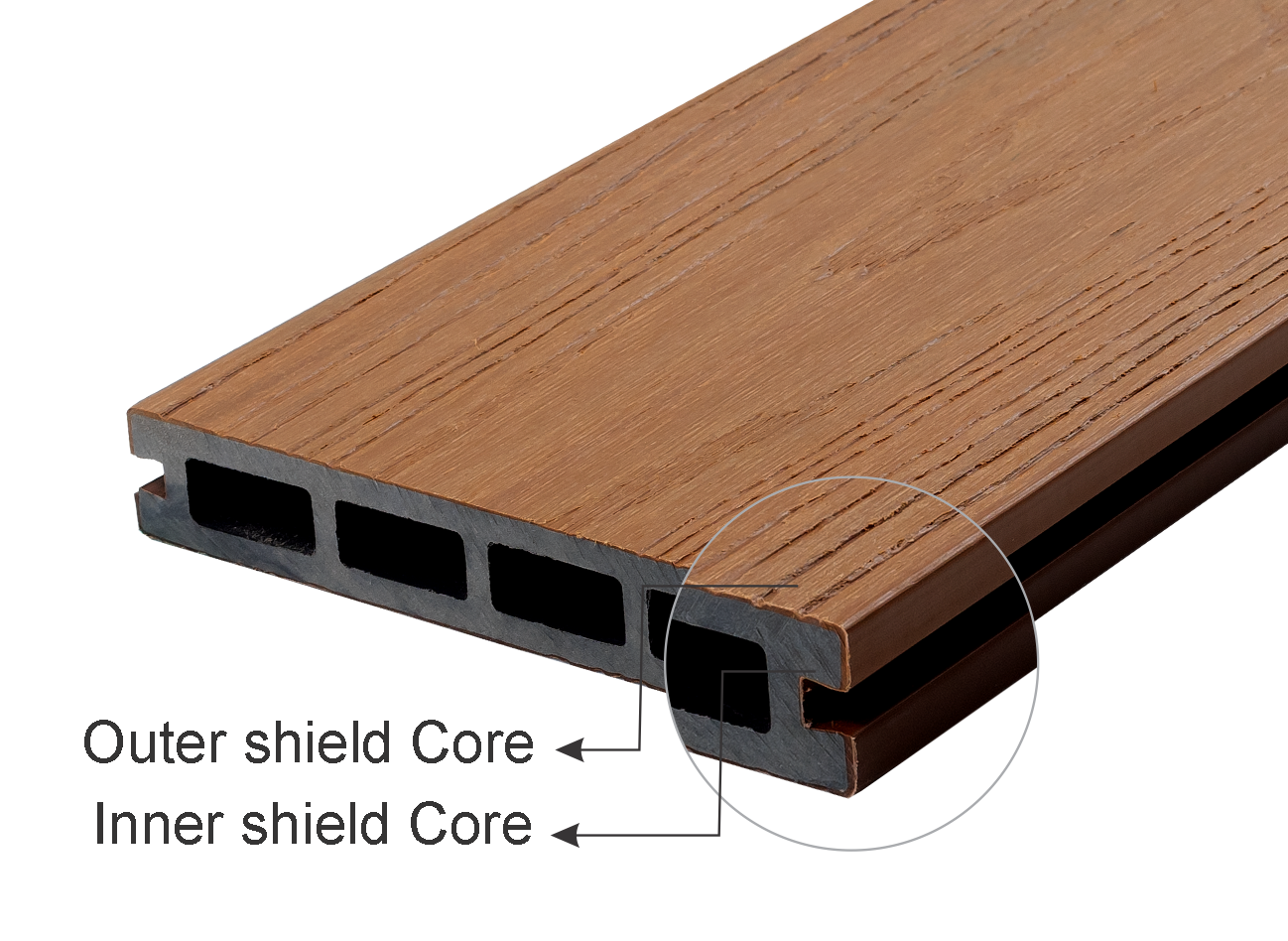

Everwood Durashield products have an inner standard WPC core, secured by a high density polymer capped outer shield layer that displays premium appearance coupled with remarkable long term performance.

- Inner standard WPC core: The inner core of Durashield products are made from a composite combination of hardwood powders, 100% recycled HDPE, filling, binders and additives.

- Outer co-extruded shield: Durashield products have an outer capped layer co-extruded along with and encasing the inner core giving the products more premium aesthetics with far greater long term durability.

Why Use Co-extrusion Technology Durasheild

Ultra good looks: Durashield products look far more premium and beautiful when compared to standard WPC products especially in outdoor decking & exterior cladding applications.

Ultra durable: The co-extruded outer cap layer makes Durashield products far more UV resistant and less susceptible to fading or discoloration, delivering much higher weathering capability.

Ultra low maintenance: Durashield’s outer layer encasing standard WPC core makes the products less vulnerable to scratching, staining or mildew and much easier to maintain.

The Difference - Co-extrusion WPC Vs Standard WPC

Co-extrusion WPC, capped WPC or second generation WPC is different and a

technological improvement from Standard WPC, also referred to as first

generation WPC. Co-ex WPC is designed with an outer cover layer that is

bonded to the inner core during manufacturing. The inner core is a blend of

wood and plastic, co-extruded and capped with an outer shield layer to ensure

the final product is very strong and resilient to weathering, while maintaining a

better wood feel over a longer periods of time.

The process of co-extrusion involves use of a non-organic surface material with

antioxidants and UV inhibitors to cover and protect the inner core.

WPC

products that are co-extruded are much better with increased performance

and durability of the products with lower maintenance.

While the cost of co-extrusion WPC products are marginally higher by

about 25% when compared to Standard WPC, the trade of in terms of better

looks, exponentially better performance and durability with much less

maintenance makes co-ex WPC a far better choice specifically for WPC outdoor

decking and WPC exterior cladding.