WPC – A Truly Versatile Material

Inherent characteristics of WPC make it a highly versatile material with key benefits such as natural wood aesthetics, high durability in exterior conditions, high weathering capabilities, UV resistance, low maintenance, lower investment and lifetime costs, fire retardant, insect proof, anti-corrosive and most importantly being environmentally sustainable.

The demand of the manufacturing and construction sector for WPC has seen a surge in the presence of the material in recent times regardless of the market situation. Being a novel and innovative material that is versatile in its applications, WPC has become a material of choice in the construction sector simply because it redefines aesthetics, quality, durability, and ease of application.

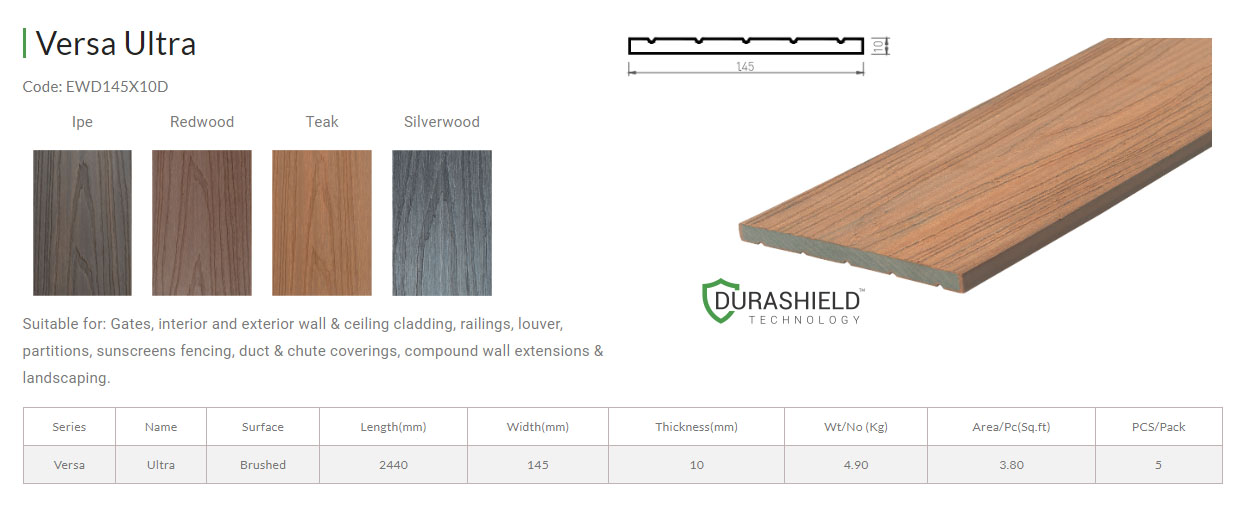

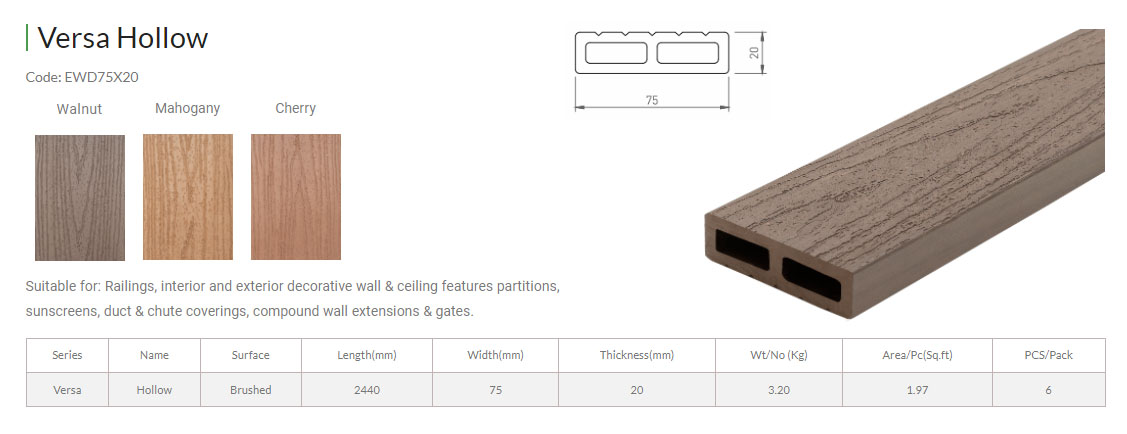

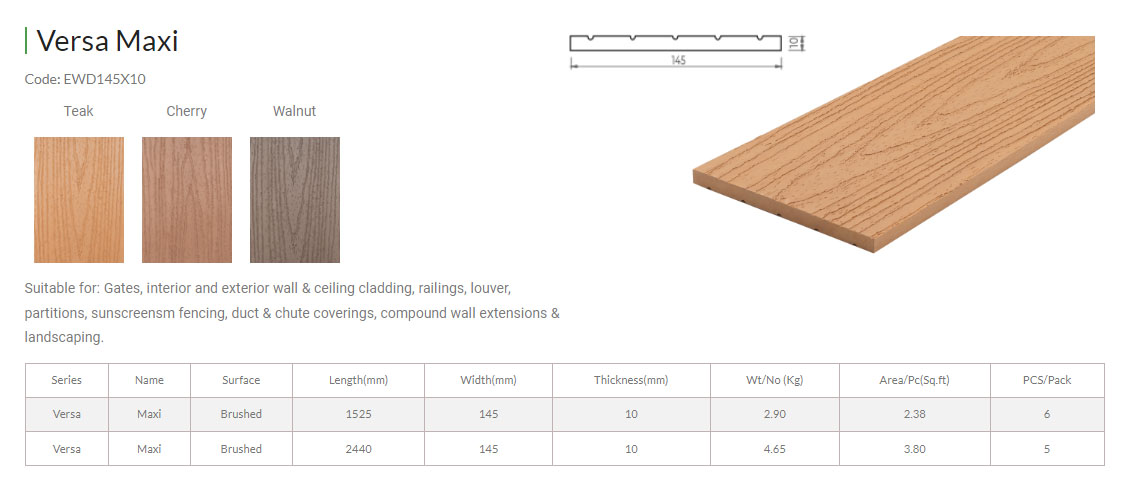

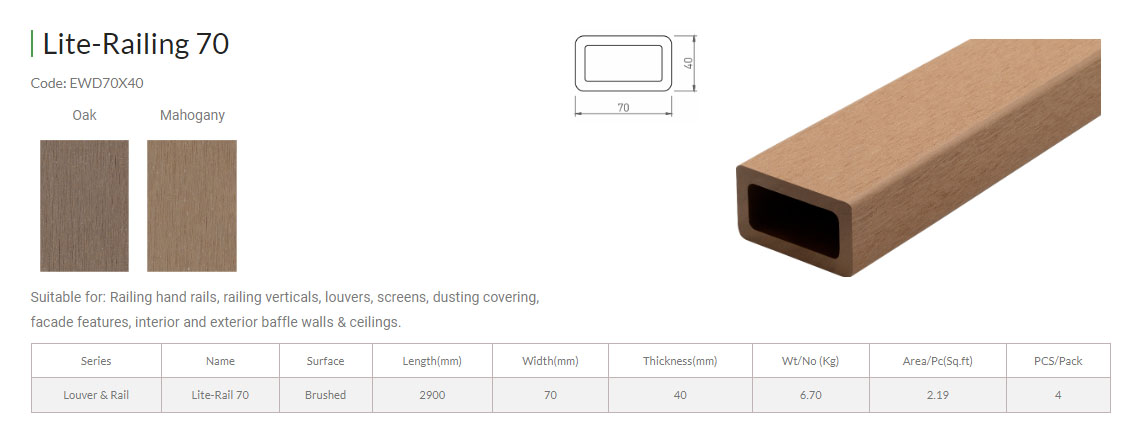

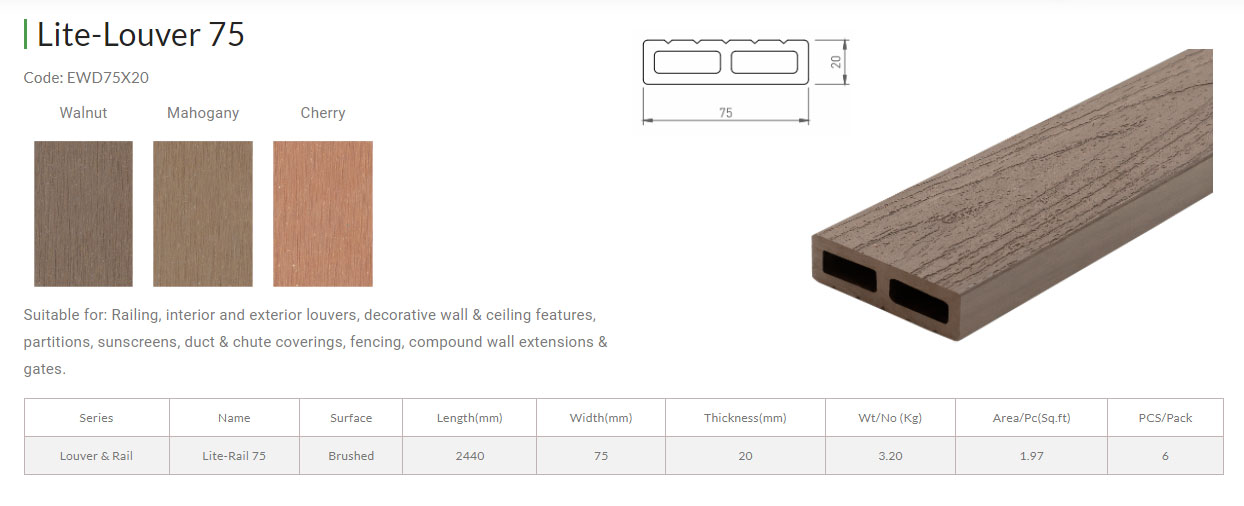

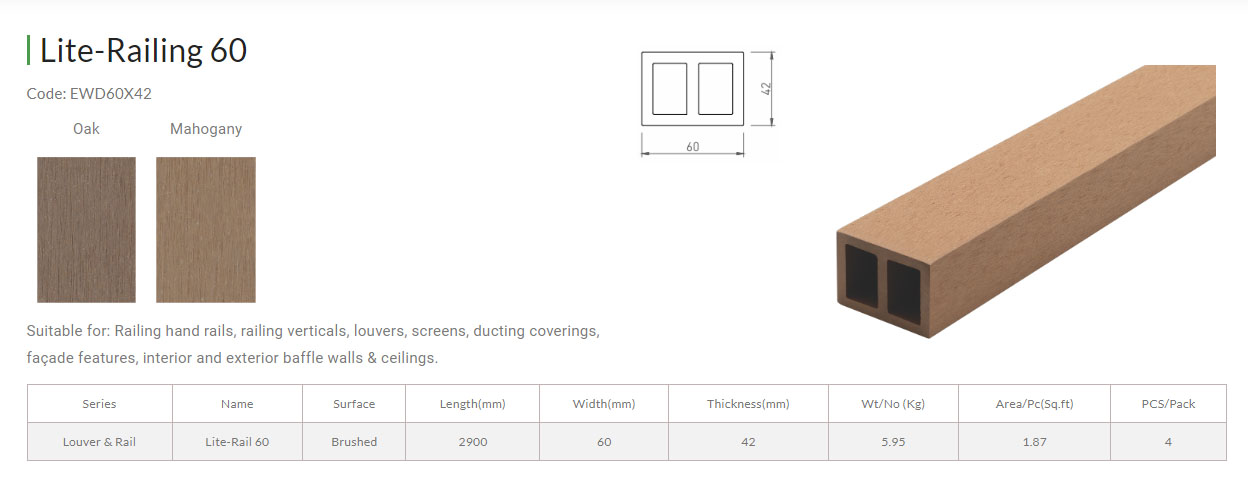

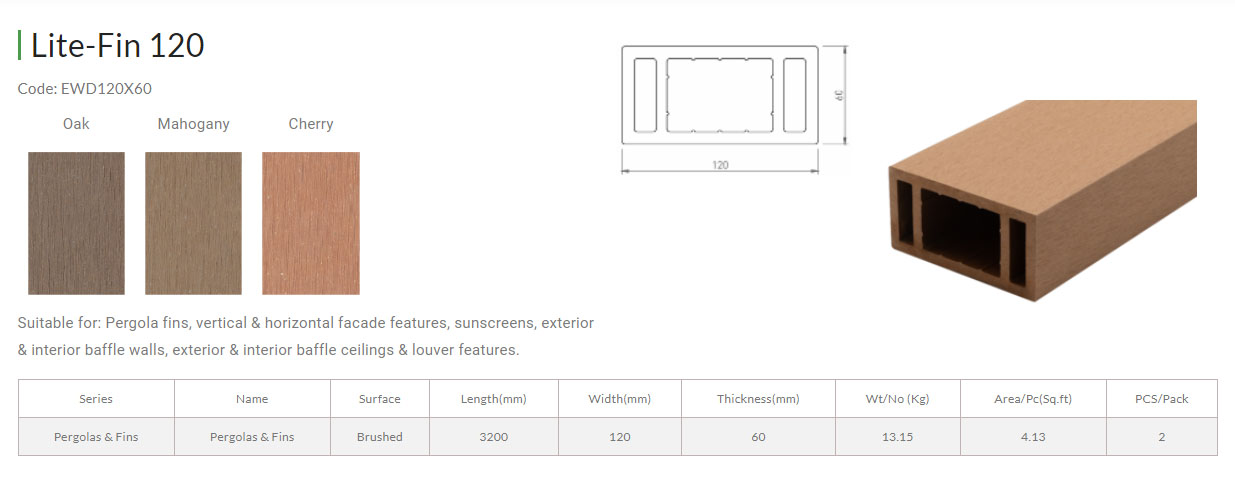

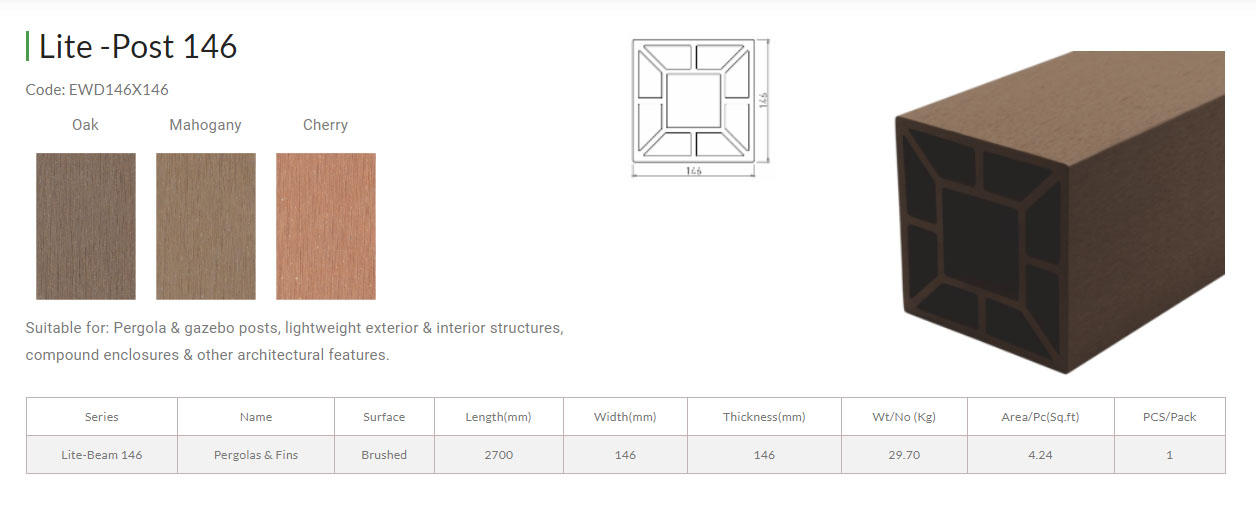

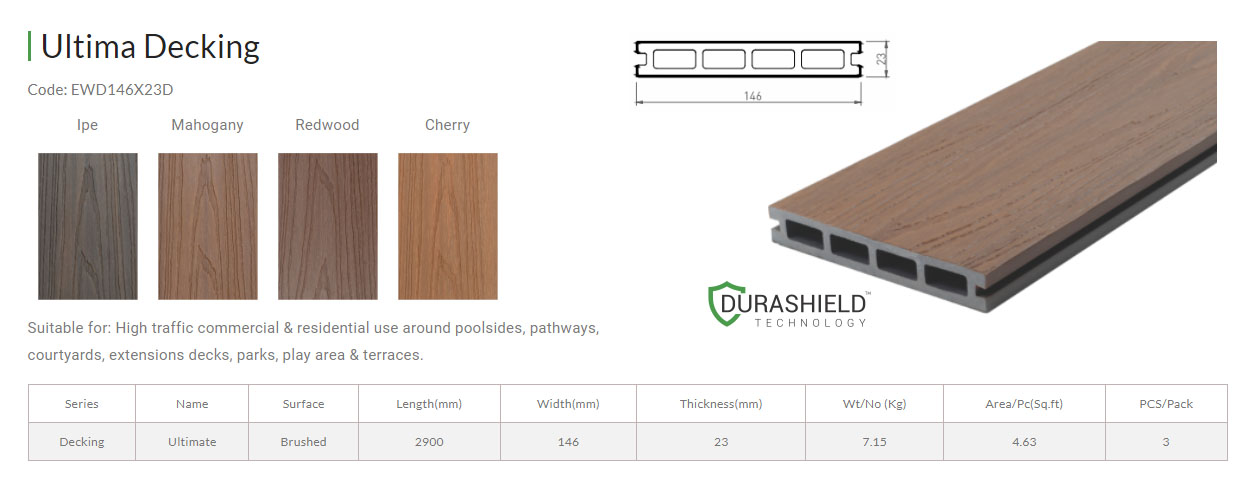

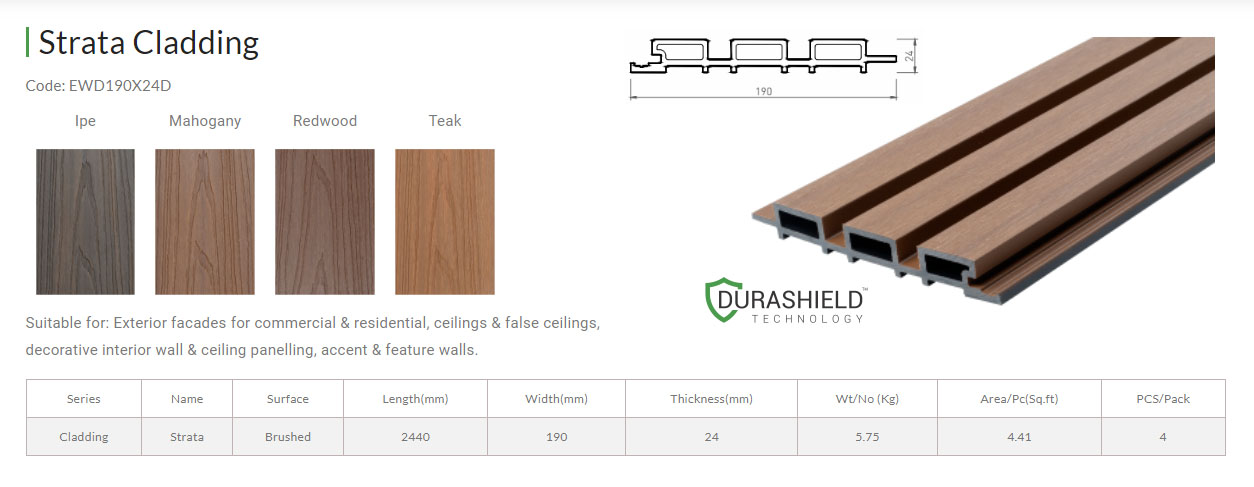

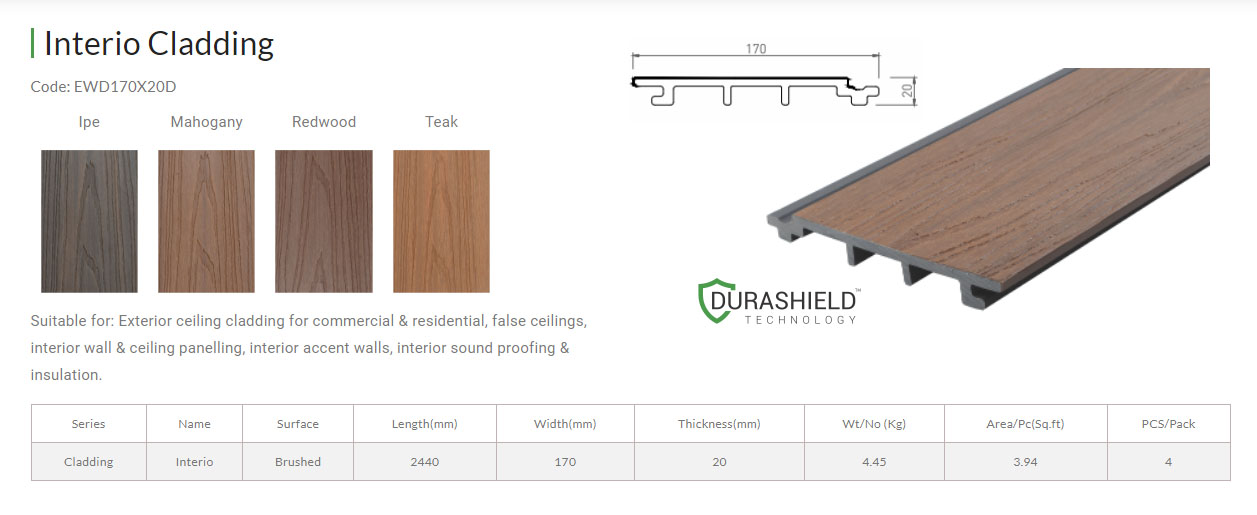

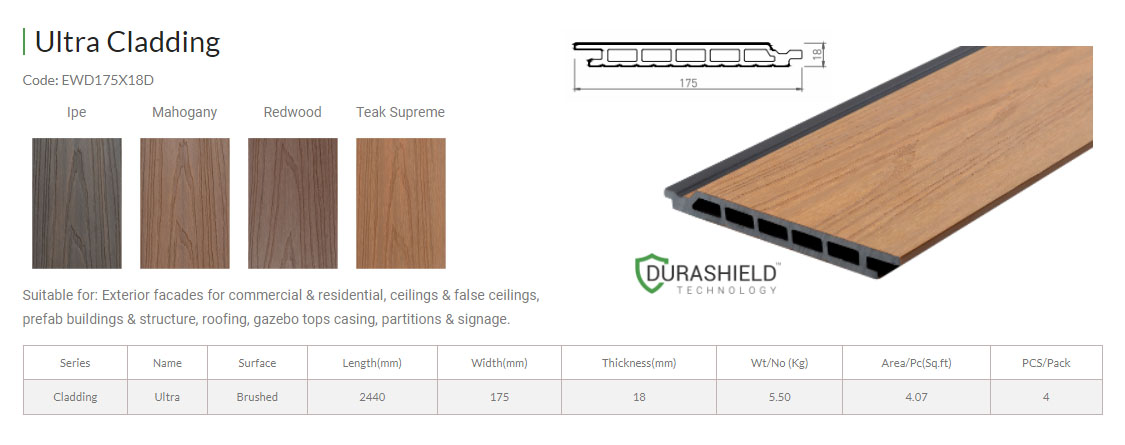

Being an extruded material, WPC can be custom-made to various shapes and sizes to suit the product application acquiring specific properties of the material to deliver superior characteristics over other conventional building materials. Since WPC profiles can be extruded as hollow profiles, cost reduction per unit of volume in WPC is also easily achieved during production.

The versatility of design, color, and finish allows WPC to be manufactured for various applications, particularly for the building material and construction industry. Conventionally used for exteriors, WPC is fast replacing conventional materials like wood, aluminum composite, HPL panels, fiber cement boards, and other materials for exterior cladding, outdoor decking, exterior and interior architectural features, and lots more.

More so, WPC frees its users from common problems like fading and deterioration with exterior exposure that is associated with materials like wood, HPL, and other similar materials. Recently WPC has seen a rapid increase in volumes driven by the upturn of the building industry and demand for a material that can be depended on for its aesthetics, durability, versatility, and value for money over the material lifetime.